Contact person:王先生

Cell phone:+86-15154247175

telephone:+86-15154247175

address:Huangdao District, Qingdao City, Shandong Province (Former Jiaonan City Chongwen Road 38 No. 28 Unit 2 Unit 203)

|

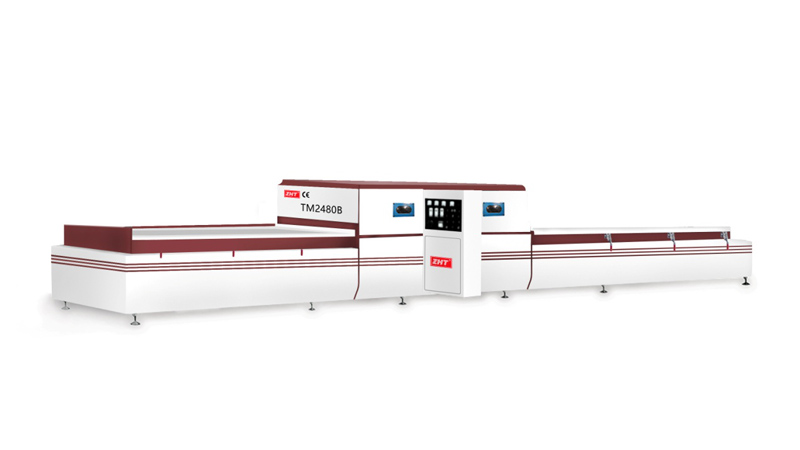

6000mm*680mm*1800mm |

|

10mm-350mm |

|

110mm |

|

|

|

15mm |

|

|

|

1.5Kw |

|

6Kw |

|

|

ADDRESSQingdao Muqiong trading Co., LTD

EMAIL283075139@qq.com

CALL US+86-15154247175